Hydrogen infrastructure faces two critical challenges: hydrogen permeation and embrittlement—both of which threaten the integrity, efficiency, and cost-effectiveness of hydrogen systems.

Traditional coatings have made limited progress in addressing these issues, but Triton Hydrogen’s Tritonex Hydrogen Barrier Coating has set a new global standard.

Independently tested by iChemAnalytics GmbH, Tritonex achieved an unmatched 94% reduction in hydrogen permeation at 100-bar pressure—a level of performance not seen in any commercially available solution. This breakthrough positions Tritonex as the leader in hydrogen containment technology.

“Industry-Leading Performance in Hydrogen Barrier Protection”

Test Summary: Setting a New Standard

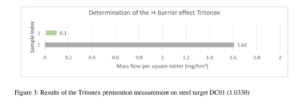

The independent tests conducted on DC01 steel under sustained 100-bar hydrogen pressure revealed game-changing results:

Test Conditions:

- Method: Hydrogen permeation test in an autoclave

- Pressure: 100 bar

- Duration: 72 & 120 hours

- Steel Sample: DC01 (1mm thick)

- Coating Thickness: ~200 µm

Results:

Sample | Hydrogen Permeation Rate | Reduction Compared to Uncoated Steel |

Uncoated DC01 Steel | 1.67 mg/hm² | N/A |

Tritonex-Coated DC01 Steel | 0.10 mg/hm² | 94% Reduction |

The asymptotic hydrogen permeation rate of the coated sample proves that Tritonex forms a stable, long-lasting barrier, preventing hydrogen from penetrating steel over time.

What This Means for Hydrogen Infrastructure

The implications of Tritonex’s breakthrough are far-reaching. By addressing hydrogen leakage, embrittlement, and degradation, this coating provides a critical solution for industries reliant on hydrogen technology.

Prevents Hydrogen Leakage & Energy Loss

Hydrogen containment is essential for efficiency and safety. Tritonex minimises leakage, ensuring more effective hydrogen storage and transport.

Extends Infrastructure Lifespan

By mitigating hydrogen embrittlement and fatigue cracking, Tritonex enhances the durability of pipelines, storage tanks, and fuel cell components.

Reduces Maintenance & Replacement Costs

Hydrogen infrastructure is expensive, but Tritonex significantly reduces the total cost of ownership by extending the lifespan of steel structures.

Accelerates the Net-Zero Hydrogen Economy

A scalable, cost-effective solution like Tritonex makes large-scale hydrogen deployment more commercially viable, supporting the global shift towards clean energy.

What’s Next?

Triton Hydrogen is actively seeking partners, investors, and industry collaborators to bring this revolutionary coating to market.

Request a Full Technical Brief – Schedule a call with our team for an in-depth discussion.

Join Our Pilot Programme – Test Tritonex in your specific application.

Explore Investment Opportunities – Speak to our investment team to be part of the hydrogen revolution.

Tritonex isn’t just another coating—it’s a transformational solution for the hydrogen economy. Stay tuned for more updates as we continue to push the boundaries of hydrogen innovation.