We would like to thank Rail Director magazine for telling the Triton Hydrogen story so well in its October 2023 publication. It is a fantastic read and, as the headline says: Tritonex is ‘An absolute gamechanger for Hydrogen in rail’…worldwide!

Rail Director Magazine is read by more than 20,000 rail professionals, internationally, every month!

The published magazine can be viewed online here: Rail Director October 2023 by RBD Media – Issuu

To talk to us about the difference Tritonex can make to your business please message us.

In an innovative move towards a sustainable future, the UK rail industry is turning to green hydrogen as the linchpin of its decarbonisation mission. This approach aims to usher in a new era of emission-free transport, poised to eclipse conventional trains that rely either on dirty fossil fuels or infrastructure-intensive overhead lines.

In a decisive move toward cleaner transport, the UK government unveiled a visionary plan in 2018: the phasing out of diesel-only trains by 2040. This ambitious commitment holds great promise for emission reduction, but its delivery is not without challenges. Currently, a staggering 29 per cent of all trains, and a massive 90 per cent of freight trains, rely on diesel propulsion. According to the Institution of Mechanical Engineers, only 42 per cent of track is electrified. Whilst increasing the electrification of the network would seem to be the obvious solution, it would be prohibitively expensive to install overhead electric lines across the entire country. The physically restrictive nature of the world’s oldest rail network and disparity in usage of different lines brings additional complexity.

The imperative now lies in identifying sustainable green alternatives to seamlessly replace these fossil fuel-dependent units without the need for expensive and complex overhead infrastructure.

An alternative to electrification

Hydrogen-powered trains have emerged as a leading solution and one of the best alternatives to electrification. One of the main benefits of hydrogen is the ability to replace trains with no change in service quality to passengers, the ability to meet existing timetables, and with minimum disruption to services, all while reducing emissions. Hydrogen is passed through a fuel cell, and through a chemical process, electricity is generated. There are no greenhouse gas emissions, and the only by-product is water. If the hydrogen is sourced from electrolysis powered by renewables, then the whole solution becomes “zero emission”.

However, this solution is not without its challenges. Hydrogen trains still need refuelling and therefore hydrogen production facilities and refuelling infrastructure will be needed.

The routes that are likely to be optimal for hydrogen are likely to be in more rural regions, suffer from restricted grid capacity or have other existing or physical constraints that make OHLs unviable.

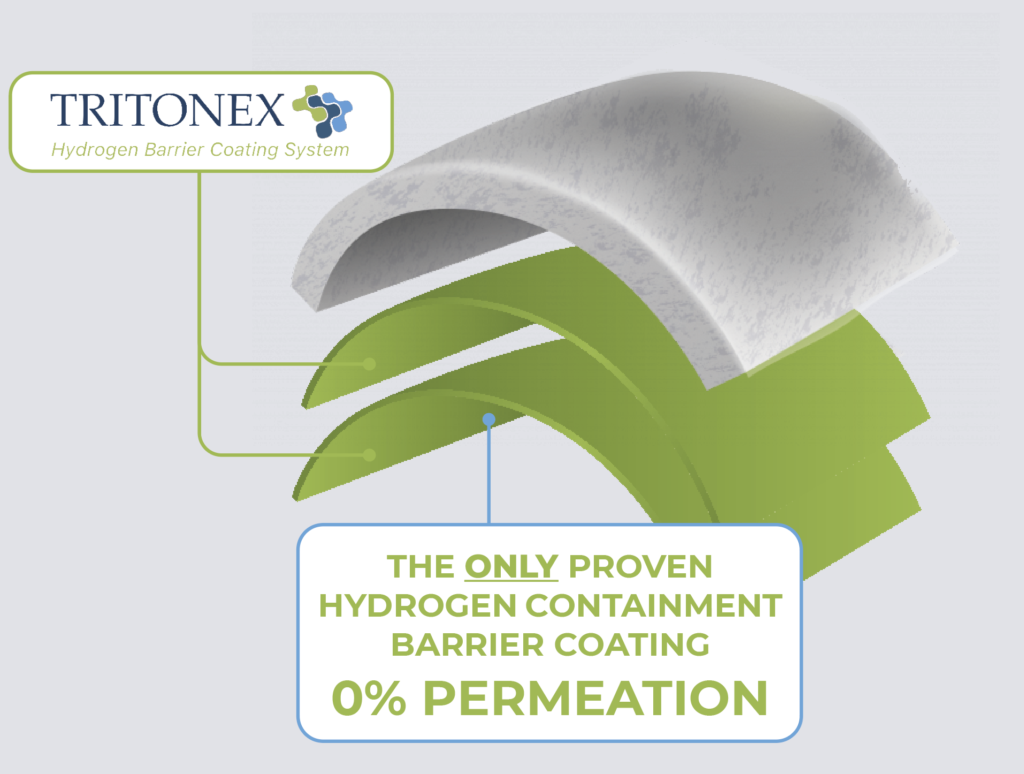

The major challenge with hydrogen as a fuel to date has been its storage and distribution. Due to its small molecular size, hydrogen escapes by permeating through gaps in the molecular structure of steel tanks and pipes. This process also causes embrittlement of the steel, eventually leading to product failure. These challenges often mean that hydrogen needs to be produced close to its point of use to reduce losses in storage and transit.

UK Innovation

Now a UK-based nano technology company has solved this problem. Their Tritonex coating uses nanotechnology to effectively seal storage tanks, pipework and valves – both on board the trains and in the supporting supply infrastructure – reducing costs and improving safety performance. The barrier coating can be applied by OEMs or retrofitted to existing products and surfaces, meaning hydrogen pipes and storage vessels can run with increased pressure without any losses, and the hydrogen can be transported over long distances in the same way that natural gas currently is.

“We need to change our mindset to realise we now can treat hydrogen as any other fuel, utilising buffer storage and long transport lines,” said Triton Hydrogen CEO Henning Syversen.

“Transport currently accounts for around a quarter of the UK’s greenhouse gas emissions, and hydrogen represents a major opportunity to reduce this. Tritonex overcomes the biggest hurdle of gas transport and storage, allowing for the development of cheap, safe and efficient fuels cells and ancillary refuelling infrastructure. Tritonex is the only solution in the world that fully complies with the ISO 17081:2014 hydrogen permeation standard.”

Whilst investment is still needed to develop a national hydrogen rail infrastructure, this is still orders of magnitude cheaper than installing OHL equipment – and with much fewer track possessions required. And with the major challenge of hydrogen permeation overcome, hydrogen could be the way to power the UK’s green railway of the future.