Triton Hydrogen has unveiled its game-changing Tritonex Hydrogen Barrier Coating System – a solution to the long-standing hydrogen containment challenge.

Certain quests redefine the frontiers of possibility in the landscape of scientific discovery. Such is the story of Triton Hydrogen, a saga of innovation and the relentless pursuit of a solution to a 100-year-old problem. The story begins with visionary Henning Syversen, the CEO of the R&D company Triton Norway. Syversen and his team embarked on an ambitious mission: to contain the most elusive molecule in the Universe – hydrogen.

Hydrogen, despite its promise as a clean energy source, has long been a slippery challenge. Its tiny molecular size allows it to escape even the tightest of confines, including permeating through solid steel. A group of talented scientists at Triton Norway took on the momentous challenge, combining nanotechnology, electrochemistry, and material science to contain hydrogen and help unlock its vast potential for our planet.

Many other organisations, including scientists at world-renowned institutes, had tried and failed to create a hydrogen barrier and spent billions. Until now, nobody has succeeded in creating a 100% impermeable barrier that does not react to hydrogen.

Grappling with hydrogen and solving the problem

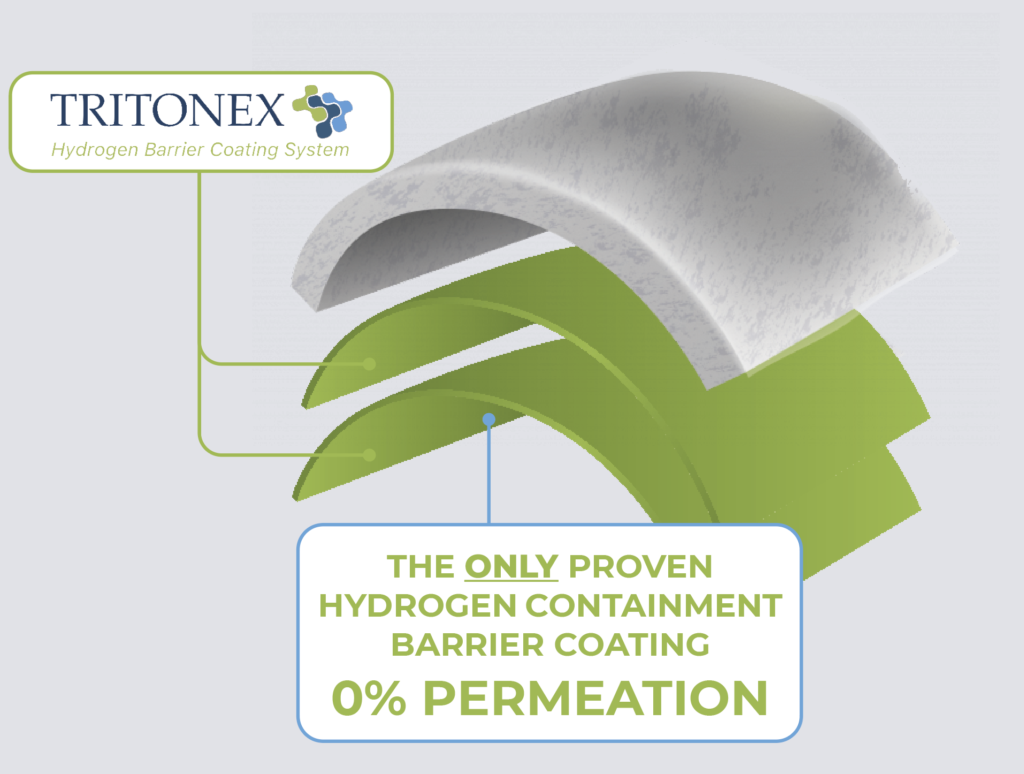

Triton’s journey took on an epic narrative in a world grappling with environmental challenges. Like alchemists of the modern age, Syversen’s team harnessed the enigmatic secrets of nano-sequencing and electro-osmosis. Their pursuit was not without trials and tribulations. Each failure was a teacher, each setback a catalyst for greater resolve. Against the odds, they developed the Tritonex Hydrogen Barrier Coating System (HBCS) – a nano-engineered marvel that heralds a new era of energy efficiency and environmental stewardship.

Tritonex’s genesis marked the birth of Triton Hydrogen Ltd in the UK, a testament to the team’s visionary approach and commercial acumen. Tritonex wasn’t merely a scientific breakthrough but a green revolution in disguise. Tritonex HBCS may seem like an ordinary paint product which can be easily applied using all of the traditional methods from brush to spray gun, but its water-based composition holds the secret nano-ingredient.

Tritonex has other properties too. It is electrically inert and does not react to any chemicals, which means it stops corrosion entirely – another remarkable property. Tested to temperatures of over 1,000°C, Tritonex is designed to withstand extreme temperature variations, and it is remarkably flexible and able to follow the thermal expansion and contraction movements of pipes and storage vessels. It is non-toxic, ensuring safety in handling. Its smooth surface also provides flow assurance.

Its unique properties, including barrier efficiency, position it as an indispensable tool for the hydrogen infrastructure, storage, and transport sectors. It emerges as a universal solution, applicable across substrates from steel to composites, carbon fibre, plastic and even rock.

Every manufacturer across the hydrogen value chain and every sector will benefit. Wherever hydrogen is involved, you need a hydrogen barrier containment solution; you need Tritonex.

The real magic of Tritonex lies in its versatility. It can be applied manually and robotically, making it a boon for original equipment manufacturers (OEM) and field retrofitting. Tritonex has shown zero hydrogen permeation in rigorous tests, attaining its ISO 17081:2014 certification – the only barrier coating to hold this ISO – a feat that cements its place as a leader in containment technology.

Read the rest of this article on the Innovation News Network covering the applications of Tritonex and what the future holds for Triton Hydrogen.