We read with great interest the recent article in Hydrogen Insight detailing the United States’ ambitious plans for massive cost reductions in hydrogen for deployment in transport and industry within this decade.

Immediately, it became apparent that Triton Hydrogen is exceptionally well-positioned to assist in these efforts.

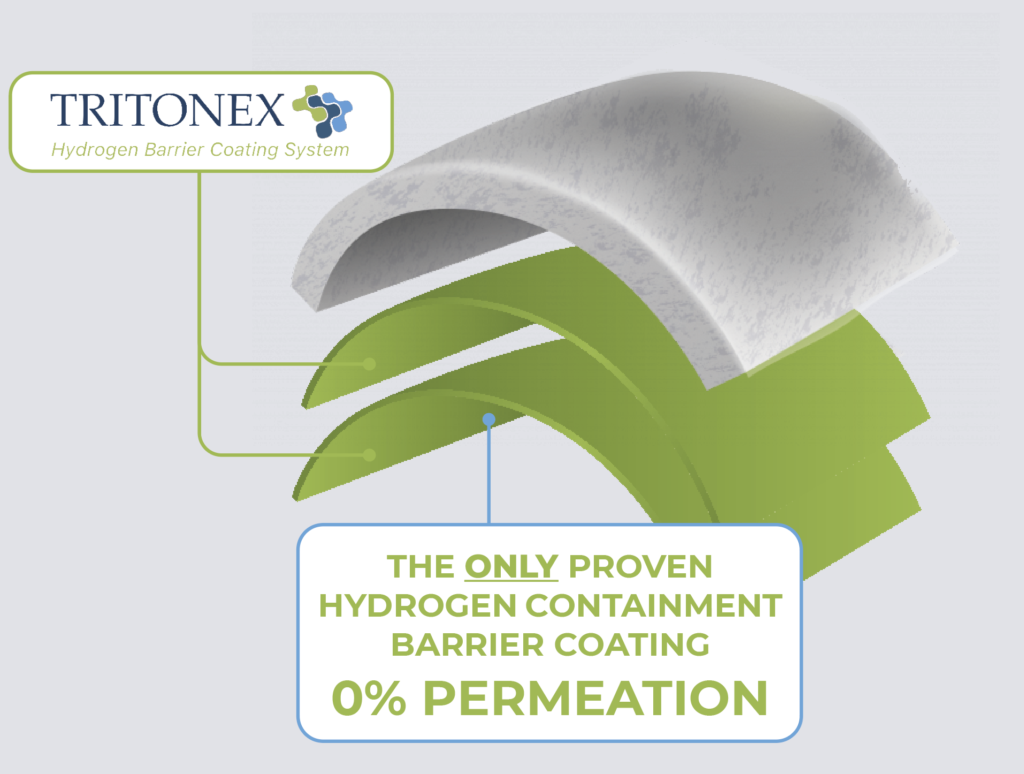

Our pioneering technologies, particularly the Tritonex Hydrogen Barrier Coating System, align seamlessly with the outlined objectives of the Hydrogen and Fuel Cell Technologies Office (HFTO). By enhancing the efficiency, safety, and cost-effectiveness of hydrogen storage and transportation, Triton Hydrogen stands ready to support the U.S. government’s push towards a more sustainable and economically viable hydrogen infrastructure.

Here’s how we align with and can significantly bolster their outlined objectives

Cost Reduction in Hydrogen Production and Dispensing

Tritonex, our flagship hydrogen barrier coating system, effectively prevents hydrogen permeation and leakage, addressing one of the most significant cost drivers in hydrogen infrastructure—leakage and associated material degradation. The HFTO’s goal to reduce the cost of green hydrogen production to $2/kg by 2026 and $1/kg by 2031 can be substantially supported by integrating Tritonex into storage and transportation systems. This integration will minimise the loss and the need for excessive raw material use, driving down production costs.

Enhanced Infrastructure Efficiency and Longevity

Our technologies can help achieve the HFTO’s target of halving heavy vehicle hydrogen costs by 2028. Tritonex enhances the integrity and lifespan of hydrogen transportation systems and fuel-cell vehicles by preventing corrosion and hydrogen embrittlement, which is crucial for heavy-duty transport applications like trucks and buses.

Advancements in Storage and Dispensing Technologies

As the HFTO seeks to improve hydrogen dispensers to an average fill rate of 10kg per minute by 2025, Triton Hydrogen’s solutions in materials technology can facilitate these upgrades. Our coatings ensure the robustness and efficiency of dispensers and storage systems under high throughput and high-pressure conditions, aligning with the agency’s ambitious throughput and compression speed targets.

Supporting Zero-Emission Vehicle Adoption

With federal mandates for zero-emission vehicles in the public sector by 2035, Triton Hydrogen’s technologies can play a pivotal role. By improving the safety, efficiency, and cost-effectiveness of hydrogen fuel systems in vehicles, we support the broader adoption and reliability of these technologies, ensuring they meet governmental and environmental standards.

Sustainability and Environmental Compliance

The HFTO’s emphasis on sustainability is mirrored in our commitment to environmental conservation. Our products, like Tritonex, are non-toxic, REACH certified, and designed to minimise ecological impact. This commitment supports the HFTO’s goals for clean hydrogen applications in various sectors, including industry and power generation, by reducing operational emissions and enhancing the environmental safety of hydrogen technologies.

So, to sum it all up, Triton Hydrogen’s innovative solutions, particularly the Tritonex Hydrogen Barrier Coating System, align directly with the HFTO’s strategic goals to reduce costs, enhance efficiency, and support the sustainable expansion of hydrogen technologies across various sectors.

By partnering with Triton Hydrogen, the HFTO and all of the companies involved could leverage cutting-edge nanotechnology to expedite the achievement of these ambitious targets, fostering a more sustainable and economically viable hydrogen ecosystem.

(Banner photograph: Jennifer M. Granholm, Secretary of U.S. Department of Energy)